The Green Place

Radiant Insulation Information

The Green Place markets both radiant barrier and reflective insulation. We are a Canadian distributor for a major American supplier. The products we carry are heavily tested against many specifications to ensure their quality. They are all built around a metalized film approach. They are non-toxic, non-carcinogenic, easy to handle, and require no maintenance. Unlike many other products, they meet ASTM E84 and E2599 fire codes which gives them a Class 1 / Class A fire rating.

Radiant barrier

We stock three grades of radiant barrier, which vary slightly in properties and applications. All are available in 500 and 1000 foot rolls that are 4 feet in width. They are designed to meet ASTM C1313 specifications for sheet radiant barriers for building construction applications. Additionally, they have been tested to comply with other ASTM specifications:

| Emissivity1 | 0.05 |

| Reflectivity1 | 95% |

| Fire Safety2 |

flame spread: 0 smoke development:as low as 5 overall rating: class a / class 1 |

| Resists | fungi3, corrosion4, cracking5, bleeding5, and delamination5 |

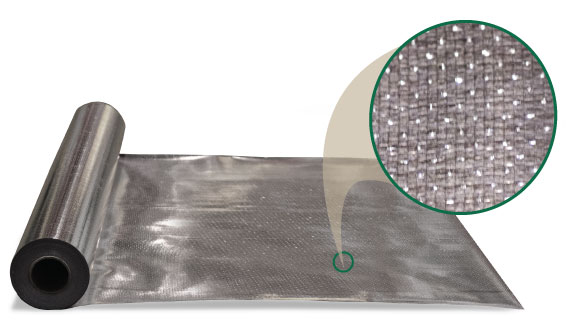

Industrial Grade

Our best product is designed for industry. It can be used as building wrap, on top of the rafters, or inside the rafters. Finally, it can be used underneath radiant heat flooring. It is reinforced with a polyethylene weave that is similar in texture and appearance to tarpaulin material. Specifications:

| Weight | 33.2 pounds per 1000 foot roll |

| Tear strength6 |

along length: 24.59 pounds along width: 21.49 pounds |

| Permeability7 | 8.19 Perms |

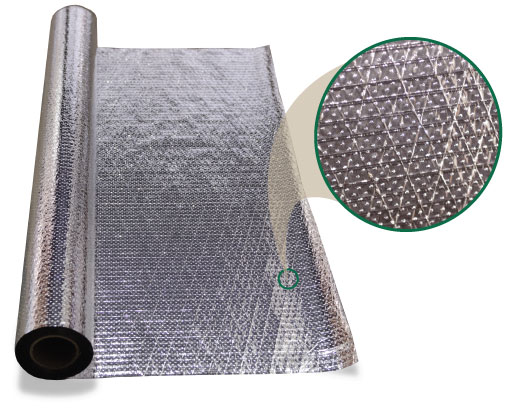

Residential Grade

For residential applications that require some strength, this grade may be preferred. It is reinforced with cross-laminated polyolefin.

| Weight | 16.35 pounds per 1000 foot roll |

| Tear strength6 |

along length: 4.53 pounds along width: 4.48 pounds |

| Permeability7 | 6.3 Perms |

Consumer Grade

Our least-expensive grade, this product is no less reflective than the above grades, but is somewhat more delicate. It is especially useful for residential retrofit and attic insulation. It is reinforced with polyester scrim. This is the only product that scored more than 5 in smoke development2.

| Smoke development2 | 10 |

| Weight | 16.35 pounds per 1000 foot roll |

| Tear strength6 |

along length: 2.32 pounds along width: 1.50 pounds |

| Permeability7 | 9.6 Perms |

Footnotes

- ASTM C1371-04a

- ASTM method E84-10

- ASTM C1338-08

- ASTM D3310-00

- ASTM C1313-05

- ASTM D2261-07a

- ASTM E96-05

Reflective insulation

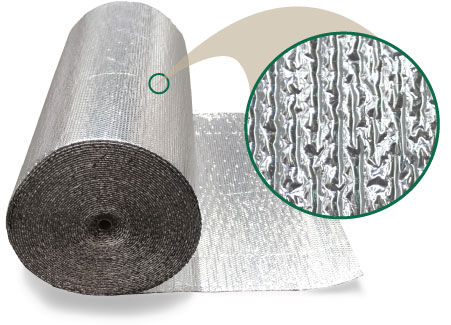

Our reflective insulation comprises one or two layers of bubble

film laminated between one or two layers of metalized film. In the

case where only one layer of metalized film is used, white

polyethylene is substituted. It provides similar properties to the

radiant barrier products, with the additional advantage of

providing conductive insulation. It will re-radiate only 5% of heat

in which it comes in close physical contact with, compared to the

approximate 90% re-radiation of ordinary building materials at the

same temperature. It is an excellent reflector of all long-wave

radiant heat that strikes it, reflecting up to 95%. Depending on

installation technique, it can provide insulation values anywhere

from R1.1 (compact subfloor installation) to R16.8 (between floor

joists with air space).

(above: 2 foil-layer, 1 bubble-layer reflective insulation)

Our reflective insulation is available in rolls 4, 5, and 6 feet

wide, comprising 300 and 500 square feet of coverage. We can also

provide 8 and 10 foot widths by special order. The thickness varies

depending on the number of bubble layers. Each layer adds 1/8".

(above: 1 foil-layer, 2 bubble-layer reflective insulation)

| Contact Temperature Range | -60 to 180 (°F) |

| Water Vapour Transmission | 0.02 perms1 |

| Puncture Resistance | 60 lbs/in |

| Flame Spread2 | 0 |

| Fire Rating2 | Class A/Class 1 |

| Resistant To | linear shrinkage

brittleness mold and mildew |

Smoke Development2

| Bubble Layers | Film Layers | Value |

| 1 | 1 | 20 |

| 1 | 2 | 25 |

| 2 | 1 | 20 |

| 2 | 2 | 40 |

Footnotes

- ASTM E96-05

- ASTM method E84-10

R-Values

This table assumes use of the double-bubble, double-film insulation.

| Application | R-Value |

| Side wall, conventional framing, including R12 fibreglass batt | R 19.56 |

| Block or basement wall, double furring | R 7.01 |

| Block or basement wall, 2"x2" furring | R 4.24 |

| Block or basement wall, 1"x1" furring | R 3.30 |

| Between floor joists, with air space | R 16.8 |

| In floor slab, compact, no air space | R 1.1 |

Roofing Thermal Values

Metal building construction was tested using a corrugated metal exterior, 1/2" extruded polystyrene thermal breaks 5' on center, our insulation, and 8" Z purlins commonly used in metal buildings. Post-frame construction was tested using a corrugated metal exterior, 2" x 4" purlins, our insulation, a 2" x 6" to represent the top cord of a truss, and 1/2" wafer board. The thermal values are for both exposed insulation and applications where the insulation is covered for fire codes.| heat flow | U value | ||||

| construction | up | down | up | down | |

| metal | wafer board | 5.02 | 7.93 | 0.199 | 0.126 |

| metal interior | 4.29 | 7.29 | 0.233 | 0.137 | |

| exposed to interior | 3.63 | 7.26 | 0.275 | 0.138 | |

| post frame | wafer board | 6.93 | 15.11 | 0.066 | 0.144 |

| metal interior | 6.22 | 14.40 | 0.161 | 0.069 | |

| exposed to interior | 4.91 | 12.81 | 0.204 | 0.078 | |

All thermal values are corrected for frame loss. "Exposed to interior" values include the thermal resistance of the interior air film: 1.32 up and 4.55 down. In the post-frame case, K-values are equal to U-values.

Wall Thermal Values

Metal walls were tested with an assembly consisting of corrugated metal exterior, 1/2" extruded polystyrene thermal breaks, our insulation, 8" Z girts, and 1/2" wafer board to represent an interior finished wall.Post-frame walls were tested with an assembly consisting of corrugated metal exterior, 2" x 4" girts, insulation, a 4" x 6" to represent the support beam, and 1/2" wafer board as an interior wall covering.

| construction | heat flow | u-value | |

| metal | wafer board | 5.45 | 0.183 |

| metal interior | 4.77 | 0.210 | |

| exposed to interior | 4.50 | 0.222 | |

| post-frame | wafer board | 6.93 | 0.144 |

| metal interior | 6.22 | 0.161 | |

| exposed to interior | 4.91 | 0.204 |

All thermal values are corrected for frame loss. "Exposed to interior" values include thermal resistance of 1.70 for interior air film.